SUCCESS STORY

How Inpixon's INTRANAV solution helped a leading international supply chain management and logistics company with digital recording of truck delivery and standing times, FIFO, and productivity monitoring to ensure optimal production supply

Read More Download PDFWith over 2,000 locations worldwide, the corporate group is one of the world’s leading providers of global logistics services, supporting industry and commerce in the international exchange of goods through land transportation, air and sea freight, contract logistics, and supply chain management.

At the ramp entrance or in the truck line, the goods unloading and receipt times are very tight. Each truck supplier is given various time slots in which the goods must be delivered and removed. If the supplier exceeds these slots, so-called penalties (contractual penalties in transport law) are applied, as further delivery processes are blocked. This is particularly challenging for companies with connected production, as they are dependent on “just-in-time” deliveries. The company to which the delivery is made is responsible for providing proof. An inconsistent time recording system can lead to unwanted costs, placing the receiving company in a disadvantage.

The factor “time” continues to run through the entire intralogistics process; if the incoming goods times are not recorded correctly, FIFO (first in, first out) tracks cannot be occupied correctly either, which is relevant for production supply.

Many of our customers operating large plants, experience high turnover rate. If the number of containers handled is not monitored and there are fluctuations in the material flow, production can be delayed.

Read about the solution INTRANAV, an Inpixon company, implemented to optimize incoming goods and monitor the KPIs of the container turnovers in real-time for our customer, one of the leading companies in supply chain management and logistics solutions.

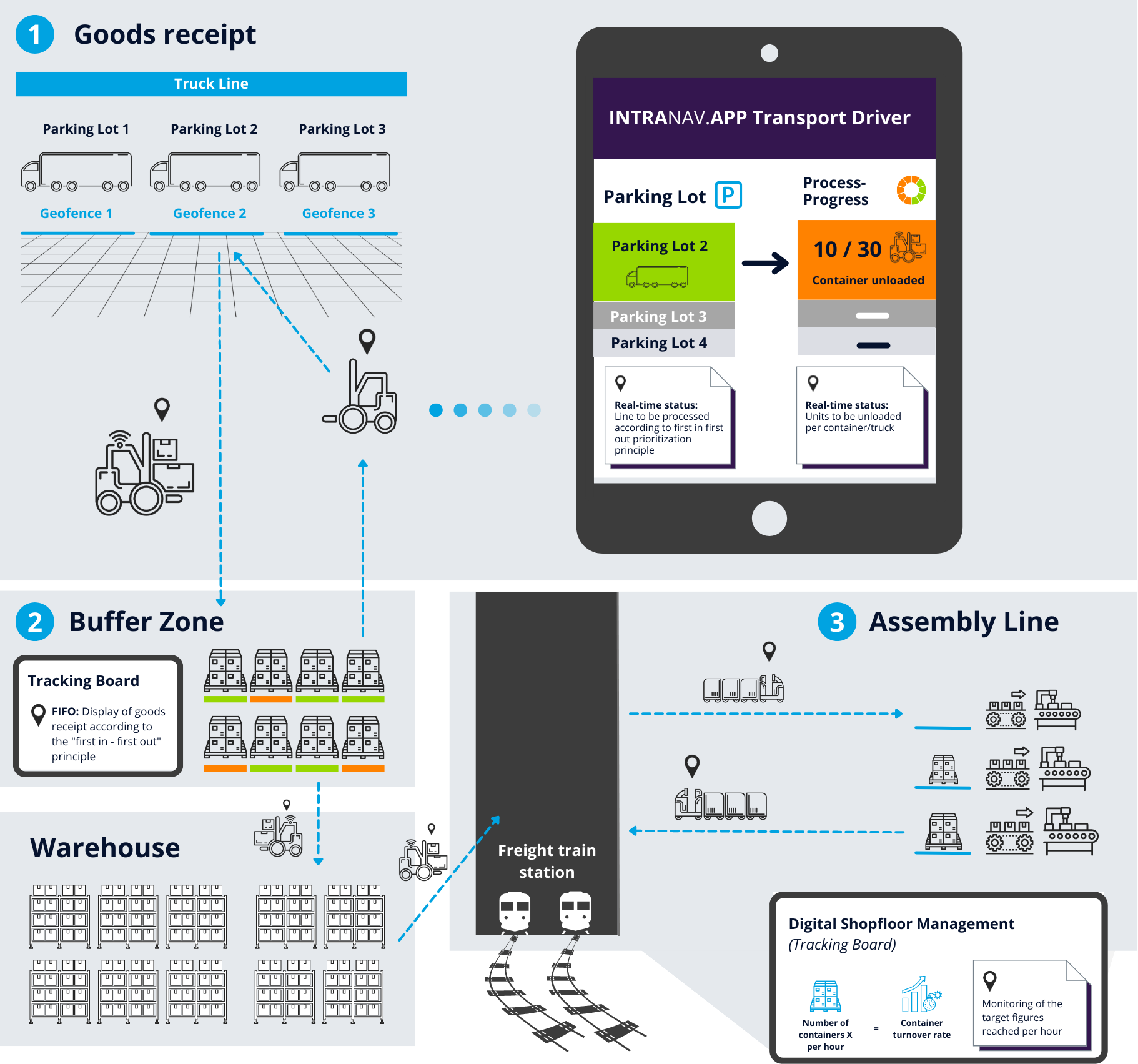

Digital forklift support according to the FIFO principle

For an automated and seamless recording of incoming goods during the truck unloading process.

Digital truck delivery and standing time logging

Complete and correct truck delivery and standing time logging.

Digital coordination at the FIFO tracks

Correct allocation of goods receipts according to the FIFO principle at the FIFO tracks/buffer zone.

Digital productivity monitoring

Control tool for the frequency of container handling, measured according to container transport of the forklift and route train fleet (from the warehouse to the supply of the goods to the production line).

Process illustration: Intelligent material flow and shop floor management

Goods receipt – Goods intake and material supply – Production supply

Digital forklift support according to the FIFO principle

Digital real-time system logging of truck standing times

Digital shopfloor management

Using INTRANAV.APP Transport Driver and INTRANAV.RTLS, our customer achieved the following results: